ISO Standards on coverall and gowns

European Protective Workwear/Gown standards

Apparel is also regulated by the PPE Directive 89/686/EEC. Most of our workwear will fall under the minimal risk category. However certain items are also regulated by specific industry standards.../../

EN340: General Requirements for Protective Clothing

Defines general requirements for ergonomy, product design and comfort, sizing requirements according to wearer height, chest and waist circumference and specific labelling of the garment. ../../

· Type 4: Liquid spray Hazardsm../../

· Type 5: Dry particles Hazards../../

· Type 6: Liquid splashes Hazards../../

In order to classify coveralls into types, specific industry standards require specific standards:

Specifies the requirement of protective clothing against Infective Agents such as Bird Flu.

Specifies the requirement of protective clothing against Radioactive contaminations.

Specifies the requirements and test method for measurement of electrostatic charge decay.

Gowns In Operation or Isolation :

Level I : Standard Surgical Gown - low fluid surgeries ../../

Level 2 : Material Reinforced Surgical Gown - low to medium fluid surgeries

Level 3 : Zone Impervious - critical zone i.e. abdomen & sleeves have panels of impervious fabric; procedures involving significant volume of fluids, e.g. transplants ../../

Level 4 : Wet Procedure Surgical Gown - an impervious apron from sternum to the base of the gown. For high fluid procedures e.g. Urology../../

Le Breathable Impervious - Supercool range only. Impervious all-over protection made from breathable material to maximise comfort.

防护服分类标准

防护服在全球不同地区都有广泛的应用,并满足不同地区防护用品认证标准的需求。其中较为严谨的是美国OSHA分类标准和欧洲EN分类标准,以保证人员在使用过程中安全、快捷。

美国OSHA(备注:Occupational Safety and Health act美国职业健康与安全法案)将防护服按其不同应用分为如下ABCD四个等级:

A级 气密性防护服

1.一般要求:需要与空气呼吸器及化学防护靴、手套配合使用。

2.主要应用:最高等级的呼吸和皮肤危害同时存在时,以及在未知危险环境中应用。

A级防化服能抵御工业生产中几乎所有危害化学品(包括气态、液态或固态),以及任何危险物质。固A级气密性防护服在国际上被誉为最强的防化服。整套服装必须配置正压式空气呼吸器或是长管式空气呼吸器,已达到密闭性。该类型全封闭防护服,必须定期对气密性进行检测,以保证使用中的安全。

B级 大量喷溅型防化服

1.一般要求:需要与空气呼吸器及化学防护靴、手套配合使用。

2.主要应用:最高等级的呼吸危害和较低等级的皮肤危害同时存在时。在已知对皮肤无影响或不能渗透,仅对呼吸系统造成威胁时配备。

B级防护服,要求呼吸防护等级达到A级,而皮肤防护等级相对低于A级,能够防止液态物质的渗透,但不能防止有害蒸气或气体的渗透。该类防护服,主要侧重于液态有毒物质防护,而非气态有毒物质。

C级 少量喷溅型防化服

1.一般要求:一般需要与过滤式防毒面具及化学防护靴、手套配合使用。

2.主要应用:较低的的呼吸危害和较低等级的皮肤危害同时存在时。在已知对皮肤无影响,并已了解环境中有毒物质成分及浓度时配备。

C级防护服,对皮肤防护等级与B级防护服相当,但呼吸防护等级相对低于B级。能够防止有毒液态物质的喷射,但不能防护有毒蒸气或气态物质。

D级 普通防护服

1.一般要求:适用于一般工作环境,对使用者可能接触到的有害粉尘、化学试剂起到最初级的防护作用。

2.主要应用:粉尘防护、少量低浓度化学液体喷溅。

D级防护服,低级防护服装,对皮肤及呼吸系统均不具备防护性能。在已知气体物质环境,对人体无害且无液体喷溅时配备。

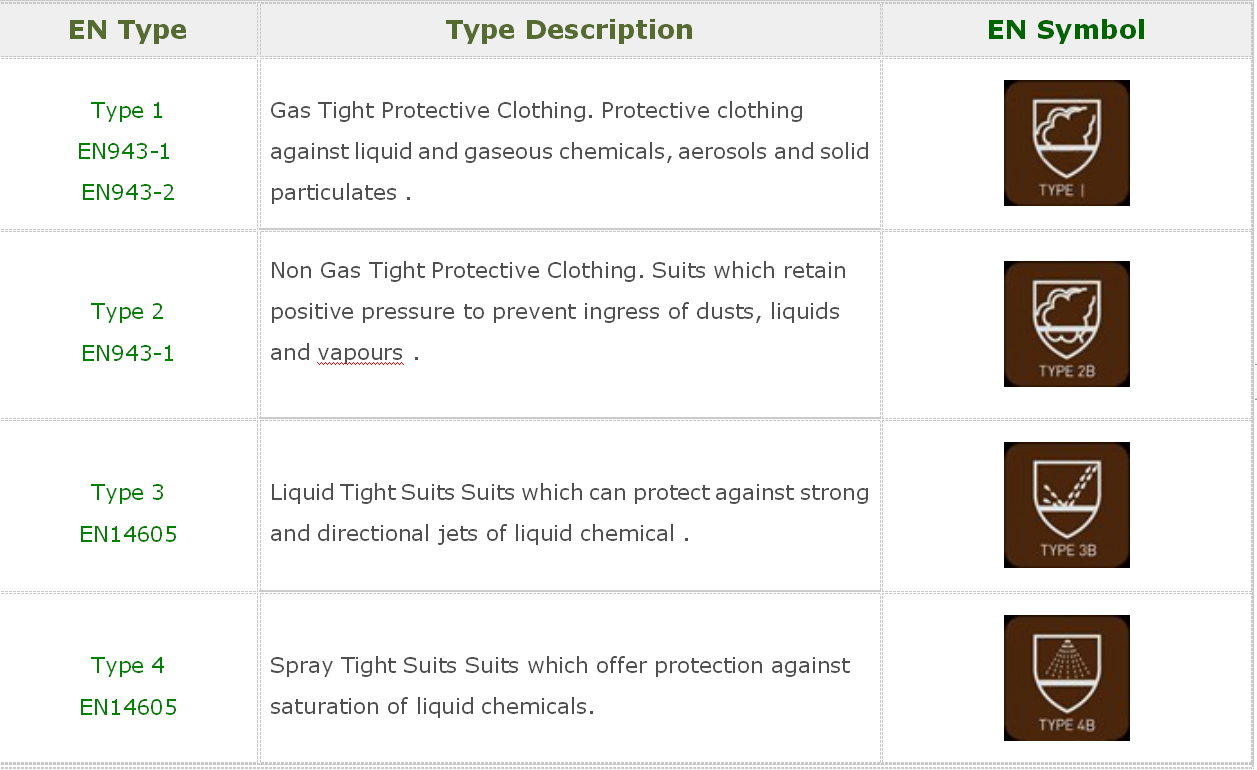

欧洲标准中规定化学防护服必须符合欧标对个人防护用品(PPE)中最高危害性防护,及“Ⅲ”类要求,并定义6种不同类别的防护服,面料性能测试和成品综合性能现场实际测试后,得出下列几项分类:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COVERALL STANDARD

Category I: Simple products. Products which are not suitable to protect against any form of hazard. Category II: Intermediate products. Products which fall neither into categories I nor III. Category III: Complex products. Products which are worn or held in order to protect against any hazard which may be life threatening.

TYPE 1 EN 943-1

Gas tight suits. Suits which are intrinsically sealed against the environment. ../../

TYPE 2 EN 943-1 ../../

Non-gas tight suits. Suits which retain a positive internal pressure to prevent ingress of dusts, liquids or vapours.

TYPE 3 EN 14605 ../../

Liquid tight suits. Suits which can protect against strong and directional jets of a liquid chemical such as spray from a burst pipe under pressure. Requires a barrier fabric and sealed seams.

TYPE 4 EN 14605 ../../

Spray tight suits. Suits which can protect against saturation of liquid chemical, where volume of the liquid builds up on the suit forming pools, resulting in rivulets. Requires a barrier fabric and sealed seams. ../../

TYPE 5 EN ISO 13982-1

Dry particle suits. Suits for protection against hazardous dusts and any dry particles. ../../

TYPE 6 EN 13034 ../../

Reduced spray suits. Suits for protection against light spray and splashes of liquid chemicals where there is no directional spray or build up of liquid on the suit, but there may be a fine mist of droplets in the atmosphere.

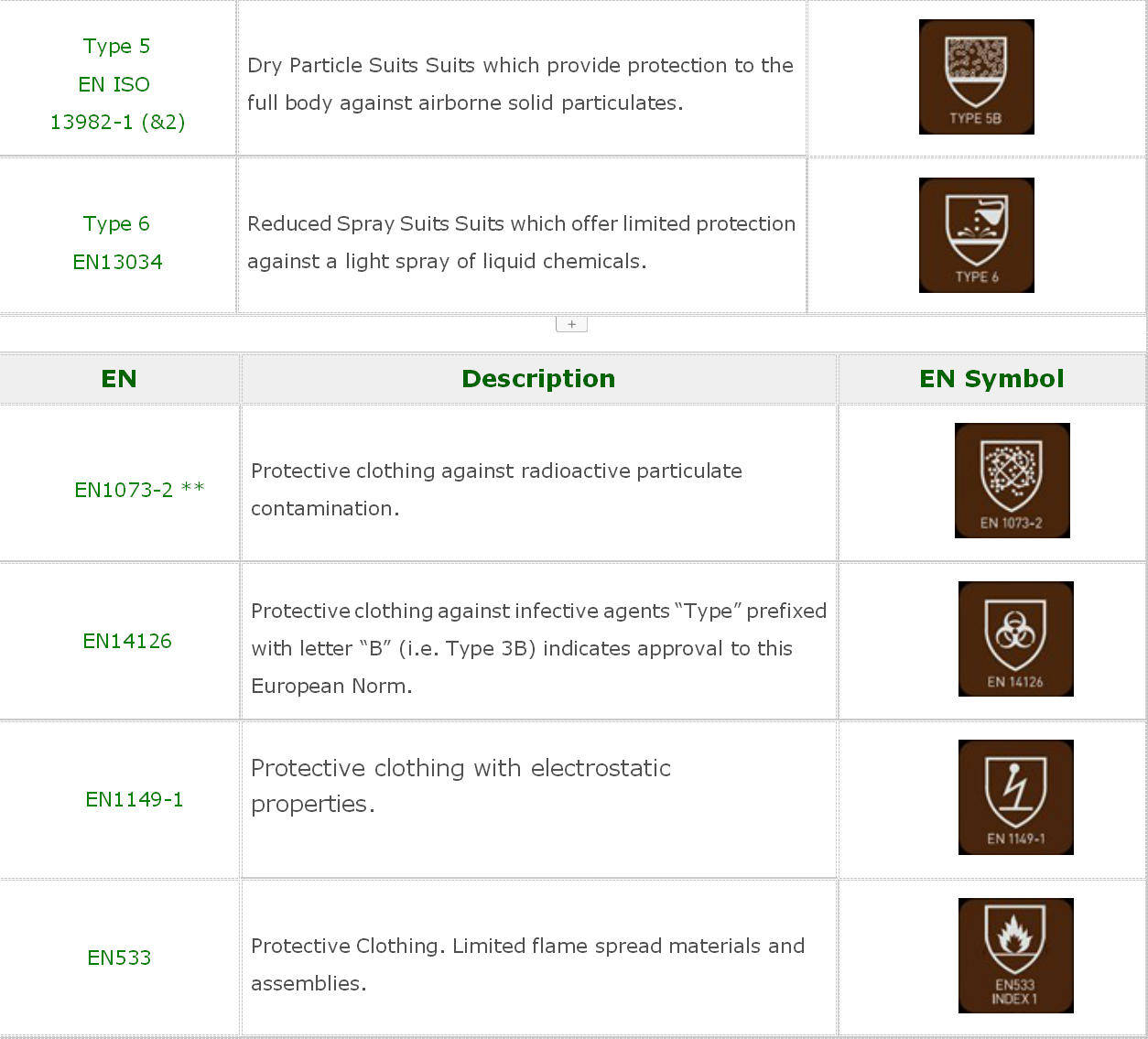

EN 1149-5 ../../

Electrostatic dissipative protective clothing with a surface resistance of maximum 2.5x 10 exp 9 ohm. ../../

EN 1073-2 ../../

Protective clothing against particulate radioactive contamination. ../../

EN14126 ../../

Protection against biological hazards and infective agents. ../../

EN ISO 14116 ../../

Limited flame spread materials, material assemblies and clothing. ../../